May 3, 2021

With a hundred years of history and tradition behind it, the company looks beyond the COVID-19 pandemic to the future of Spain’s pulse industry.

This year marks Legumbres Luengo’s centennial. Since its founding in La Bañeza in Spain’s northwestern province of León, the company has dedicated itself to the development of Spain’s pulse category, expanding its product line to change with the times while also staying true to its roots in a region of the country where pulses are part of the popular identity.

But with the world ravaged by the COVID-19 pandemic for the second consecutive year, the company decided this was not the right time for a major celebration, says Pedro Luengo, who joined his family’s business a decade ago. In March of last year, when Spain first imposed a lockdown, the company had to improvise to guarantee the health and safety of its team.

“This was challenging as there were no masks, gloves or safety equipment at all and we were working seven days a week,” recalls Pedro. “Demand surged in the first month of the pandemic, when consumers panicked and stocked up on basic items, including pulses. After that, it looked like demand would settle down, but it didn’t.”

Spain is one of the leading pulse consuming nations in the European Union. Pedro estimates annual consumption at 180,000 – 200,000 MT. With typical production of 70,000 to 90,000 MT, Spain relies heavily on imports to meet demand.

To make sure Legumbres Luengo’s 100th anniversary did not go unnoticed, the GPC reached out to Pedro to learn more about his family’s company and the pulse sector in Spain.

Pedro: I joined the family business following a few years in the institutional investments department of an international real estate consulting company and after completing my MBA. When I started working at Legumbres Luengo, I found that I liked what I was doing and I had all these ideas about plans for the company’s future.

What I like best about the job is that, as an industrial company, we work directly with retailers. That adds pressure in many ways. We don’t just supply pulses. We also have to be constantly looking for excellence in logistics, service, new products, communication. That makes every day different.

At Legumbres Luengo, we are very proud of the value we offer with our own brand in terms of quality, reliability and the identification consumers feel with the values we promote. I think the innovation that we demand from ourselves on all tracks makes us passionate about what we do.

Pedro: The company was established in 1921 as a warehouse for agricultural products and a linseed mill. Over the years, as modern retail entered the market, the company began specializing in pulses. My father, Gaspar Luengo Asensio, joined the company at the age of 18 and was a strong believer in the value of having our own brand. He pushed the idea of the Luengo brand and acquired majority control of the company in the mid-’90s. The company is in the position it is today thanks to the fruit of my father’s labor over his lifetime.

Nowadays, Legumbres Luengo supplies pulse-based foods to retailers and foodservice providers via our own brand and private labels, as well. We cover a wide range of product types, from conventional, organic, ready-to-eat, texturized products and more. We work with dried and canned/jarred pulses. Our goal is to become our customer’s strategic partner in the development of the pulse category. In the end, our success is shared.

Pedro: We work with a wide variety of pulses. In terms of lentils, we work with pardinas, large and small greens, regular greens and whole and split red lentils. We work with a wide range of beans, including alubias, cranberries, dark reds, black eyes and black beans. And on chickpeas, we work with many different caliber sizes.

Pedro: We source both locally and through imports. Our imports come mainly from the U.S., Canada, Mexico and Argentina. In both cases, we have developed long term relationships with growers and exporters. We are very quality-focused, and it is vital that our suppliers understand what works for us and what doesn’t.

Pedro: In terms of dry pulses, lentils are at the top. They require less time to cook and there is a long tradition of cooking dry lentils in Spain. Over the years, pardina lentils have surpassed large green lentils as the preferred type.

In terms of cooked pulses, chickpeas have been selling well, gaining ground on the sale of dry chickpeas. This has had an effect on the size of the chickpeas consumed here in Spain, as smaller calibers are used for canning and jarring.

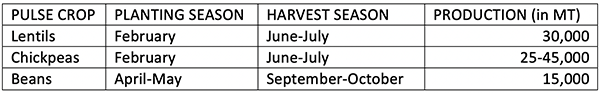

Pedro: Spain produces lentils, chickpeas and beans. Lentils are grown in Castilla and León in the northwest of the country and Castilla La Mancha, in the southeast. Chickpeas are grown in Andalucía, Extremadura and Castilla and León. Both lentils and chickpeas are seeded around February and harvested in June and July. Beans are grown on irrigated lands, mainly in Castilla and León, where the crop is seeded in April and May, and harvested in September and October.

Data from the Ministry of Agriculture indicates that lentil production (of all types) is about 30,000 MT per year on average. Chickpea production ranges from 25,000 – 45,000 MT depending on competition from alternative crops, weather conditions and pricing. Bean production has been reported at around 15,000 MT per year.

Pedro: In Spain, consumption of all pulses amounts to 180,000 – 200,000 MT. The main types that are imported are brown and green lentils, chickpeas and a variety of bean classes. It is tricky to come up with import numbers because a good part of what comes in is re-exported to Northern Africa and not actually consumed in Spain.

Pedro: There are many, fortunately! There is cocido, a dish that combines chickpeas, vegetables and different kinds of meat. Another is fabada, made with large white beans from Asturias. There is also lentil stew and potaje, which is made with chickpeas and other pulses. Most of the regions in Spain have their own traditional pulse-based dish.

Additionally, there is an increasing trend of introducing pulses into new dishes, even at non-traditional mealtimes. On our webpage and social media networks, we promote a wide range of new options for consuming pulses as a good source of healthy, plant-protein. We don’t want pulses to be a one-hit wonder!

Pedro: This pandemic has underscored how important the origin of products is for consumers. PGIs certify that certain products come from a certain area and possess characteristics such as taste or cooking traits that are unique to it. Every PGI is approved by the European Union and is subject to a board that oversees growers and industrialists to verify the label.

At Legumbres Luengo, we offer six PGI pulse products: lentils from Tierra de Campos and La Armuña, beans from La Bañeza, chickpeas from Escacena and Fuentesaúco, and fabada Asturiana.

In addition, our brands Luengo Origen and Vegas Bañezanas work exclusively with domestically produced pulses. In fact, Luengo Origen offers only PGI pulses.

Pedro: Production-wise, lentils and beans will have similar seeded areas, and we need to wait and see what the weather conditions will be. So far, lentil crops look good. In the case of beans, it is too early to tell. Due to low prices last year, chickpeas lost some hectares to competing crops, mainly to sunflower.

It is difficult to estimate consumption under the current circumstances. There continue to be different foodservice lockdowns per area, which makes it difficult to estimate demand in the coming months. My sense is that we will be far from repeating last year’s numbers. Beyond the initial panic, I think there is a tendency to eat more pulses when people eat at home. With vaccination programs and the onset of warmer weather, lockdowns should be ending soon and that might spur more consumption. We will have to wait and see to what extent.

Pedro: Our future plans are to consolidate our brand’s leadership position and, together with our customers, to build a stronger pulse category that responds to the demands of the consumer. To achieve this, we need to continuously improve our operations in order to be flexible, reliable and provide excellent service, which is such an important part of the value we offer. We must also remain close to the final consumer to understand their needs and wants.

As we move forward into Legumbre Luengo’s second century, we remain committed to the values that have gotten us this far: quality, service, transparency and innovation.

Pedro Luengo / Legumbres Luengo / Spain / USA / Canada / Mexico / Argentina / Castilla / Leon / Tierra de Campos / La Armuna / La Baneza / Escacena / Fuentesauco

Disclaimer: The opinions or views expressed in this publication are those of the authors or quoted persons. They do not purport to reflect the opinions or views of the Global Pulse Confederation or its members.