October 12, 2023

Co-Founder of Fabumin Adi Yehezkeli spoke to GPC about the search for partners in pulses, their mission to radically reduce water waste, and the future of its game-changing egg alternative.

It all started in me and my partner's kitchen after we became vegan. We used aquafaba a lot and found it was a wonderful product, but that having a liquid solution makes it difficult to use. Only when we wanted to purchase aquafaba powder for ourselves did we realize that the product was in fact quite niche, and almost non-existent due to technical problems in its production.

It took two years of experiments in the kitchen until we developed a cheap way to extract the active ingredients from the aquafaba in a dry form and from there it was a short path to a patent and the startup.

In 2020 when we got funds from the Israel Innovation Authority (IIA), me and my partner, who shares the same name as me, founded Fabumin. I’m the CEO and he is the COO, then there are two more R&D people within our staff – Assaf Cohen and Rana Nicola Haick – they are food engineers and all the magic happens because of them. Our team is 50% female and we have an amazing advisory board. We are a very small, lean company, but very keen to get to market and fulfill our potential.

Fabumin can completely replace the use of egg powders and egg protein in the food industry and has the potential to drastically reduce the use of chickens as the source for raw material.

The uniqueness of Fabumin is actually the source for our raw material: we treat the "waste" water (i.e. aquafaba) that is a byproduct of the pulse industry, drying it into a functional powder. We evaporate 80% of the wastewater, then cool it and return it for reuse in the factory as distilled water – this means we can save pulse processors up to 80% on their water bill. The remaining 20% of cooking water is dried and ground into powder to make Fabumin.

We are closing the ecological loop and creating added value for all stakeholders – the pulse factories, food manufacturers and end consumers, as well as improving our environment and animal welfare. Everyone benefits from the addition of Fabumin production in processing plants.

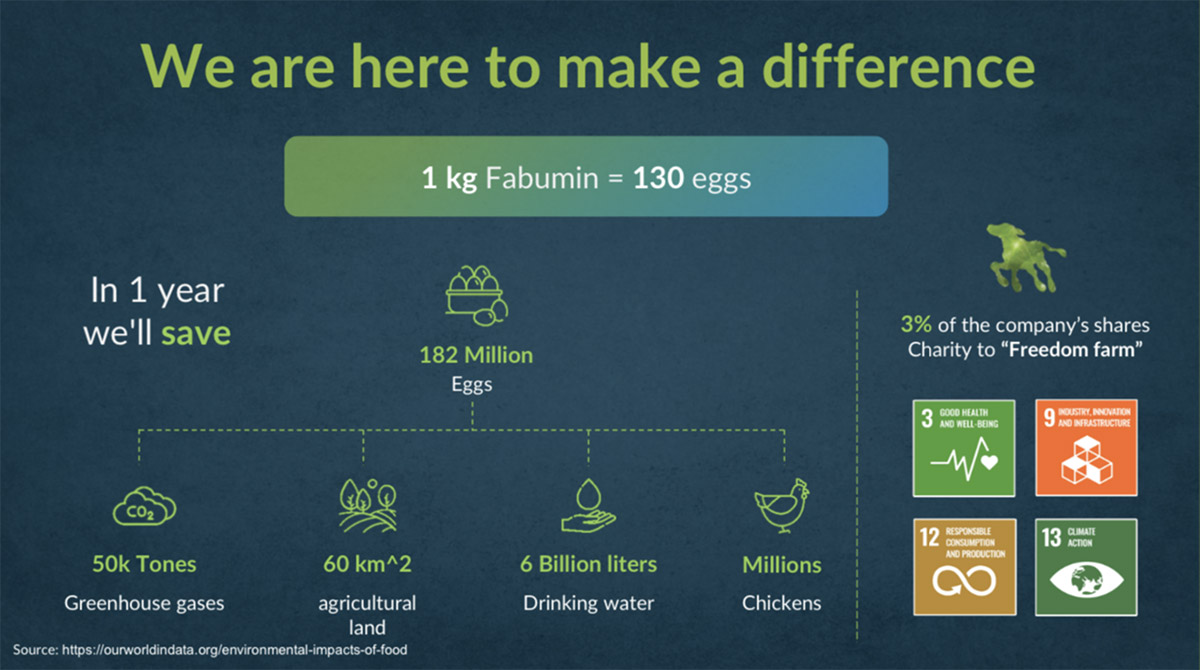

To put it into perspective, one kilogram of Fabumin is equal to one hundred and thirty eggs, but one single egg requires thirty liters of fresh water. The production of Fabumin recycles existing water use, and could also save 182 million eggs, 50,000 tons of greenhouse gas, and six billion liters of drinking water every year, while freeing up 60 km² of agricultural land and millions of chickens.

An advantage we have over our competitors is that we fulfill the great potential of aquafaba, both in the food industry and in other industries such as cosmetics, microbiome research, and plant fertilization. Our product is green, sustainable, with a long shelf life, clean label, and a fixed, stable price.

We know how to produce Fabumin from a wide variety of legumes. All prepared food suspensions – spreads, tofu, legume flours and more – all of these produce aquafaba.

Up to now we have a semi-industrial pilot that can produce 10 kg of powder every day. We're not commercialized yet, as we're still working towards our next milestone: to build a facility that can produce a ton of Fabumin daily to address the local market. This will allow us to practice selling and distributing the powder, and provide a stepping stone to upscaling to a five tonne facility in 2024.

Right now, everything depends on where we can find finance and investors – we need to source $2 million to build the one-tonne facility, which will help move us towards a five-tonne facility.

Our drying system is plug and play – specially designed to be built inside the processing factories. We only need a small portion of the factory – around 200m – in which to place our technology. We also require factories that have yield at least 50 m³ of waste water.

I invite the readers with connections to the factories that pour aquafaba down the drain to contact us – we will save them the waste treatment, recycle the water, and offer them a new growth engine for the factory.

We would prefer to build our technology into Western European factories, simply because we have connections there and have business relationships with some customers and distributors. Many factories that process pulses in Europe have to stick to regulations regarding the circular economy – we are offering them and other factories around the world an opportunity to close the loop. However, if we find partners in India, Canada, or anywhere else globally, we will definitely consider moving our production there.

Israel and many other countries in the Middle East region are in constant danger of drought, and it is only getting worse with global warming.

The fact that these countries are often also characterized by a high consumption of pulses means there are also many processing plants, which enables the reuse of a great deal of water in their industry.

Demand is expected to come from all those large food manufacturers (B2B) and end consumers looking to simply replace the use of eggs in their baked goods.

Since the price of Fabumin is the same as the price of egg powder, today we are working with fourteen international food corporations, with whom we are working to taste test Fabumin in their products. We are concentrating on the baking industry as it is the largest customer of the egg powders and holds a 45% share of the total egg powder market. We've already had great success with sponge cake that uses Fabumin!

We are aiming to sell Fabumin at the same price as egg powder. Current egg powder prices are around $15-$20 per kilo, so this will be our selling price. We're not going to add on any ‘plant-based premium’ as we want the product to be affordable and to enter the markets as fast as possible.

“We're not going to add on any ‘plant-based premium’ as we want the product to be affordable and to enter the markets as fast as possible.”

Fabumin is actually healthier than eggs. It contains more omega-3, and unlike eggs it does not contain fat or cholesterol. Although the protein content is slightly lower, this is an almost unimportant fact in the confectionery world, where the use of eggs stems from their functional properties. Fabumin even offers an alternative for those who suffer from an allergy to eggs, offering 100% food safety without fear of salmonella or bird flu.

It’s true, taste is important! There is no difference between egg powder or Fabumin – we have performed blind taste tests using cakes, and people cannot tell the difference between cakes made with Fabumin and cakes made with egg powder or liquid aquafaba. The functionality is exactly the same and there is no difference in taste.

Our vision is to enable the full industrial use of aquafaba. We see ourselves naturally integrating into the pulse industry and complementing it in a way that can be replicated anywhere in the world. We want more and more new processing plants to pre-build with our facility in them, enabling a reduction in water use from day one.

aquafaba / Fabumin / Adi Yehezkeli / wastewater / plant-based egg / plant-based / Israel / processing / future of food

Disclaimer: The opinions or views expressed in this publication are those of the authors or quoted persons. They do not purport to reflect the opinions or views of the Global Pulse Confederation or its members.